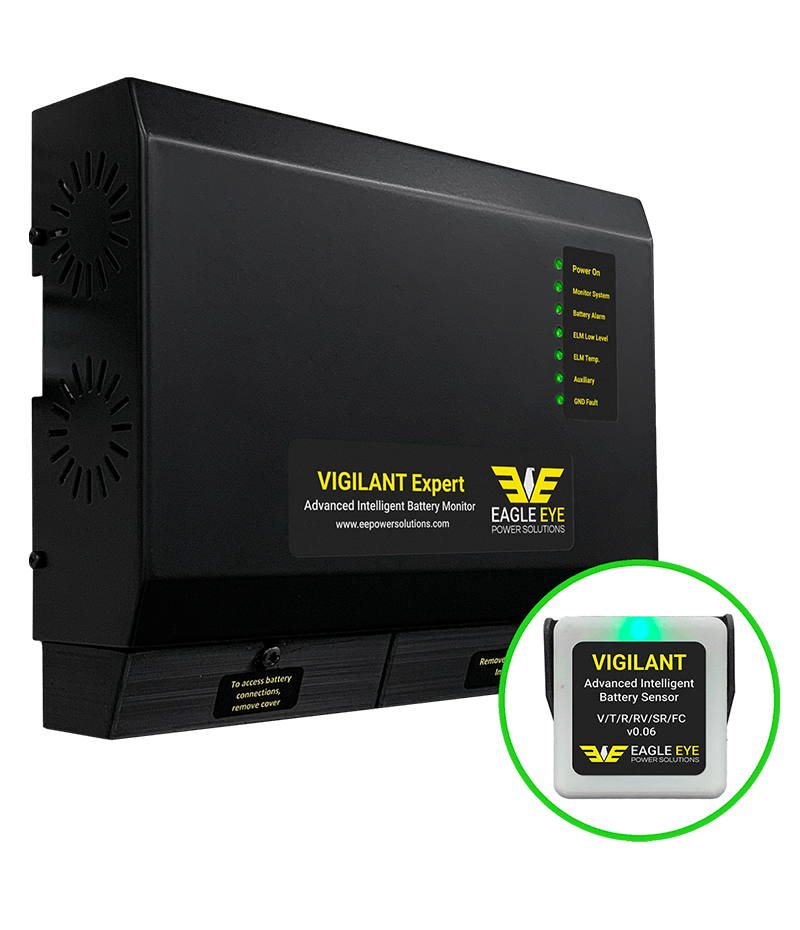

VIGILANT™

Next Generation Battery Monitoring System

The ground-breaking VIGILANT™ Battery Monitoring System (BMS) with Advanced Multi-Function (AMF) sensors employs several new battery parameters to predict battery condition. Included in these critical parameters are Battery Cell Condition, Battery State of Health, and Battery (at) Risk Factor. These new features are made possible by machine learning algorithms built into the VIGILANT™.

The following key battery parameters are monitored and recorded by the VIGILANT™: string voltage, float current, cell voltage, cell resistance, terminal & connection resistance, cell & ambient temperature, dc ground fault, and electrolyte level.

Web-Based, Remote Battery Monitoring

- A key advantage of the VIGILANT™ is how it processes measurement data

- Rather than simply read and display measured parameters, the VIGILANT™ also uses Artificial Intelligence to calculate the state of health (SoH) of the battery

- Measurement data and analysis is done via a built-in web-server, which can be accessed with any browser

- The web-based software eliminates the need for a standalone software package and is viewable on a desktop or mobile environment

Predicting Battery Condition

The VIGILANT™ utilizes several technologies new to the battery monitoring industry to predict battery failure:

- Battery Cell Condition: Using machine learning algorithms to accurately calculate deterioration much earlier than current Ohmic testing methods

- Battery State of Health: Algorithms encompassing 12 key parameters to estimate the health of the battery as a whole. It includes measured changes in internal & external factors and in all parameters that could identify a potential reduction in anticipated battery life

- Battery Risk Factor (RF): Employing individual cell SoH along with temperature and ripple current to better predict risk of battery failures

- True Float Current: VIGILANT’s™ Advanced Multi-Function (AMF) sensors measure true float current without the remanence and temperature problems of Hall-effect transducers

Visit Eagle Eye University for information on our battery training courses.