Specifications

| Measurement Range | Battery Capacity: 5 – 6,000 Ah

System Voltage: 0 – 576 VDC

Unit Voltage: 2, 4, 6, 12 VDC

Load Current: ±10,000 A

Temperature: 0 – 80°C (32 – 176°F) |

|---|

| Accuracy/Resolution | System Voltage: ±0.5% / 0.1 V

Load Current: ±2% / 0.1 A

Unit Voltage: ±0.5% / 0.01 V

Internal Resistance: ±2% / 0.001 mΩ

Unit Temperature: ±2% / 0.01° |

|---|

| Resistance Test Load | Less than 2A AC per cell |

|---|

| Measurement Interval | String voltage/current: Real-time

Cell voltage: 1 sec to 1 min (adjustable)

Resistance: 10 min to 24 hours (adjustable) |

|---|

| Communication Protocols | TCP/IP to proprietary software

Modbus TCP |

|---|

| Alarming | Form C Contacts

Email/SMS alerts |

|---|

| Operating Environment | Temperature: 0 – 65 °C (32 – 150°F)

Relative Humidity: Under 80% |

|---|

| Power Requirements | 43 – 250 VDC

110 – 220 VAC |

|---|

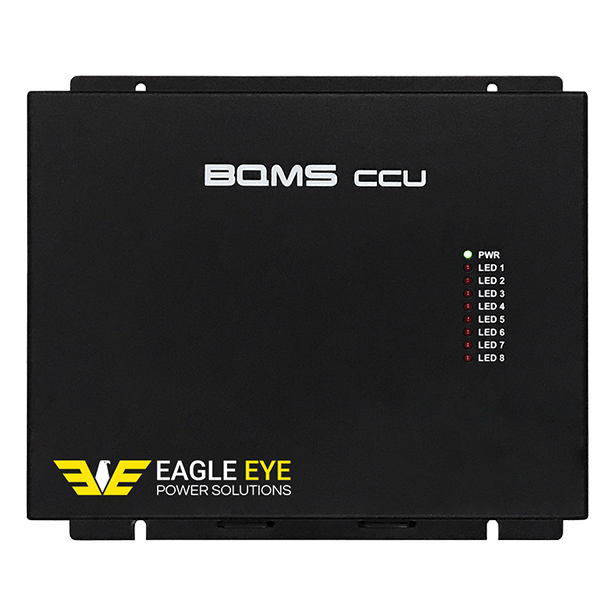

| Dimensions | CCU: 210 x 76 x 200 mm (8.25 x 3 x 7.9 in)

Module: 114 x 70 x 39 mm (4.5 x 2.75 x 1.5 in) |

|---|

FAQs

What hardware / components come with the BQMS?

A complete system will have the following components:

- Communication Control Unit (CCU) – Processes measurement data and houses communication connections to network.

- Module(s) – Mount on the battery system in a daisy chain connection. Each module connects to 2-4 cells depending on the voltage.

- Sensing Cables – Cables which connect to the BMS clamps from the MPU for gathering measurement data.

- Clamps – Physical connection to the battery system, connects to the inter-cell connections.

- CT – Hall Effect CT clamp for measuring DC current.

Does the BQMS calculate the capacity of the batteries?

No, the BQMS does not perform a load test, so there is no way for the system to calculate the capacity. The system does detect and record all discharge events to show how each cell performed during the duration of the test.

Can the BQMS monitor battery systems in parallel?

No, the BQMS is designed for testing of a single system.

How does Eagle Eye’s Centroid 2 software work?

The Centroid 2 software is composed of two parts, the server and the client. Centroid 2 Server is installed on a dedicated PC that must be connected to the same network as the BQMS system(s). This software runs in the background on a Windows environment as a service. Centroid Viewer client must also be installed on a PC that is on the same network as the BQMS. The client can be installed on multiple computers and can pull data directly from the PC with Centroid 2 Server running.

How does the BQMS test jar/cell resistance?

The system injects 400mA to 2A (max.) AC current for a duration of 900ms per jar / cell. During the 900ms duration is (3) 300ms tests. The average of these (3) tests is used as the final test result.

Does the BQMS AC measurement signal affect the battery’s condition or lifespan?

The level of AC current applied to the battery by the monitoring system during measurement is insufficient to affect battery life, as it is not continuous nor is it a of a level that could cause the temperature to rise during the short period it is applied.