At Eagle Eye Power Solutions, we align our products and services with IEEE industry best practices to help you meet the highest standards in battery maintenance, testing, and monitoring. Whether you are building out a new DC power system or maintaining existing infrastructure, IEEE recommendations provide the foundation for safety, reliability, and long-term performance.

This page serves as a helpful starting point for engineers, technicians, and compliance officers who are searching for trusted, standards-aligned battery maintenance and monitoring solutions.

Why IEEE Best Practices Matter

The Institute of Electrical and Electronics Engineers (IEEE) publishes widely adopted standards for the design, operation, and maintenance of battery and DC systems. These best practices are often referenced in NERC standards, OEM manuals, and by engineering consultants. They include:

- IEEE 450 – Maintenance, testing, and replacement of vented lead-acid batteries

- IEEE 1187 – Provides guidelines for the design, maintenance, and testing of batteries in stationary applications

- IEEE 1188 – Maintenance, testing, and replacement of valve-regulated lead-acid (VRLA) batteries

- IEEE 1106 – Recommended practice for Ni-Cd batteries

- IEEE 1657 – Training for personnel working with stationary batteries

- IEEE 1491 – Maintenance and life cycle testing practices

Staying aligned with these best practices ensures your systems are safe, compliant, and reliable, while also reducing the risk of unexpected outages.

Not Sure Where to Start?

Whether you’re working with VLA, VRLA, or Ni-Cd batteries, or building out a program for a utility, data center, or industrial site, we can help guide you toward solutions that follow IEEE’s trusted guidance. Explore our IEEE-aligned solutions:

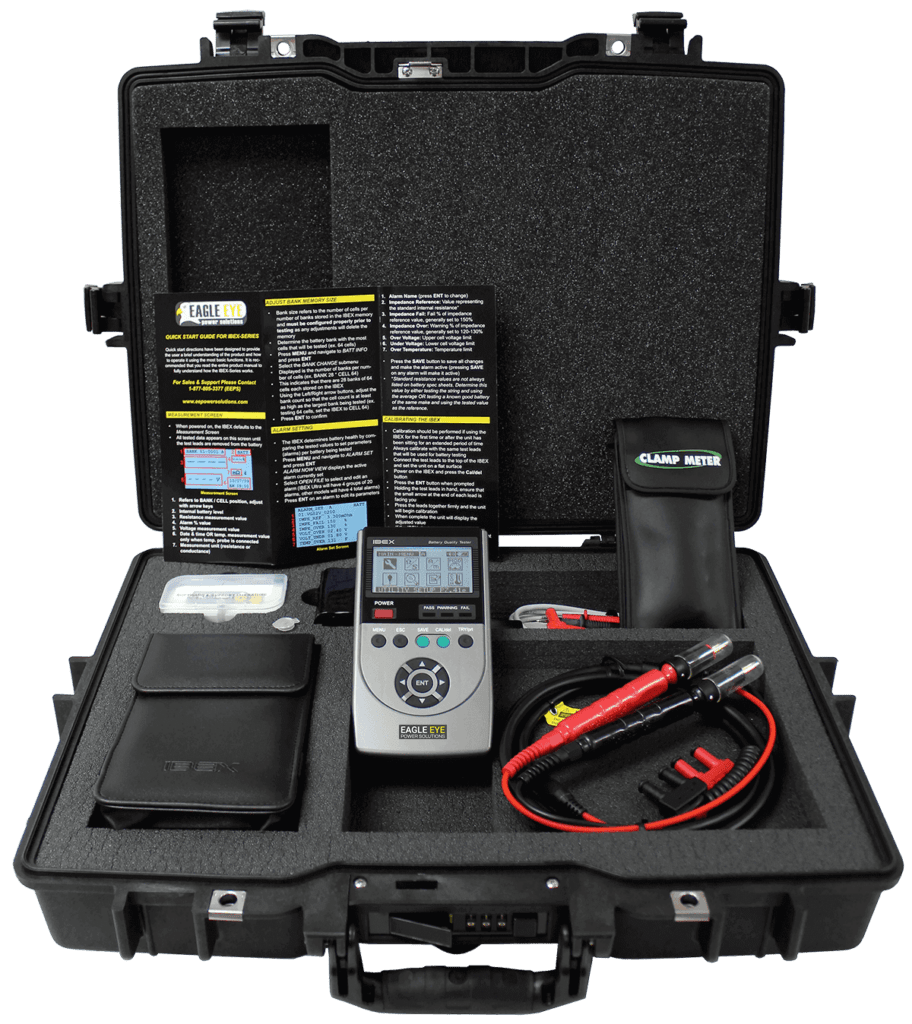

Portable Battery Testers

Conduct scheduled maintenance in accordance with IEEE best practices for maintaining batteries.

Battery Training & Certification

Training grounded in IEEE Best Practices for reliable, compliant power systems.

Eagle Eye Power Solutions’ Commitment to Excellence

We don’t just follow standards—we teach them. As an IEEE Educational Partner, Eagle Eye University’s training and content are developed with a focus on accuracy, clarity, and relevance to today’s power systems. Our experts and instructors regularly speak at IEEE conferences and work directly with clients to ensure best practices are being implemented in real-world environments.

Book a Free Maintenance Assessment

Schedule a free on-site maintenance assessment with Service Project Manager Chris Melby. He’ll inspect your battery room to ensure everything is operating safely, efficiently and meets IEEE Industry Best Practices—no obligation, just expert eyes on your critical infrastructure.

Ryan Wallace

Market Development Manager

262-518-2467

ryan.wallace@eepowersolutions.com

How Eagle Eye Power Solutions Helps You Follow IEEE Best Practices

- Condition-Based Monitoring

Capture real-time insights into battery voltage, internal resistance, temperature, electrolyte levels, and more—allowing you to make informed maintenance decisions. - Discharge Testing Tools

Meet IEEE recommendations for periodic performance testing using AC/DC load banks that validate system capacity. - Visual & Automated Inspections

Automated sensors and portable testers help reduce manual labor while still meeting IEEE inspection intervals and checklists. - Clear Maintenance Documentation

Easily log and export maintenance records and test results to prove compliance with IEEE procedures during audits or reviews. - Training Programs

Our instructors offer IEEE-aligned training—ideal for utilities and industrial clients that want to standardize their internal battery maintenance knowledge.

Ready to Build a Best-Practice Battery Program?

Let our experts help you evaluate your current systems, implement IEEE-aligned solutions, and build confidence in your battery reliability.